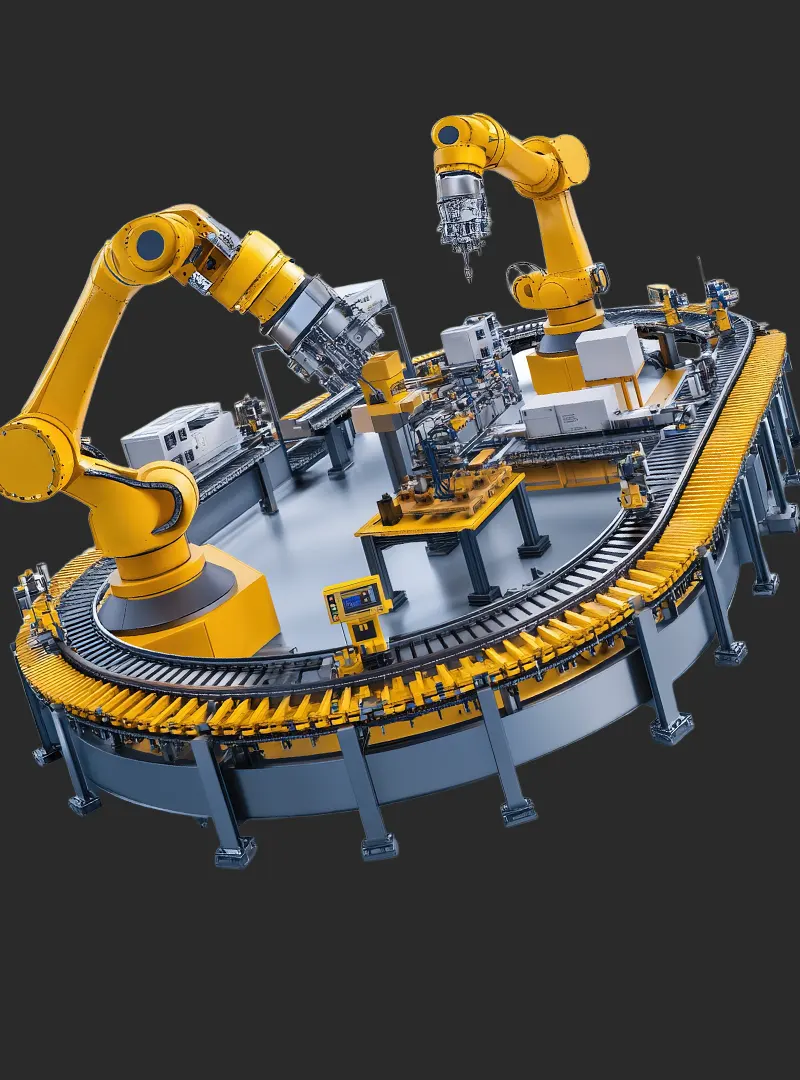

Conveyor Chain -Engineered for Material Handling

Our conveyor chains minimize environmental impact while maintaining superior performance. These chains are suitable for a wide range of industrial and agricultural applications, ensuring reliable material handling and minimizing your carbon footprint. Learn how our innovative solutions can improve your operational efficiency with durable, recyclable components that align with green principles.

Sustainable Conveyor Systems

Eco-Friendly Chains for Your Operations

Conveyor Chain: Precision equipment for Chain Conveyor Belt Systems

Conveyor chains represent fundamental components in industrial material handling systems, designed to transmit power and facilitate the movement of goods across various applications. These chains, typically constructed from durable materials such as steel alloys, ensure seamless operation by linking with sprockets to drive conveyor mechanisms. A prominent variant, the chain conveyor belt, integrates flexible chain links with belt-like surfaces to handle diverse loads, offering enhanced stability and adaptability in sectors like manufacturing, agriculture, and logistics.

The conveyor chain, like transmission chain, consists of a series of journal bearings held in precise relationship to each other by constraining link plates.This configuration minimizes slippage and wear, promoting efficiency and longevity in high-demand environments. At Ever-power, our conveyor chains are engineered to meet stringent standards, providing customizable options to optimize performance for specific operational requirements.

How It Works

Conveyor chains operate through a systematic mechanism that ensures efficient material transport in industrial and agricultural settings.

Power Transmission

The process begins with a drive motor or power source rotating the sprockets, which engage the chain links to initiate motion.

Chain Engagement

The chain’s pins and rollers interlock with the sprockets’ teeth, converting rotational force into linear movement while minimizing friction and wear.

Material Conveyance

As the chain advances along guides or tracks, it carries or propels attached loads, enabling continuous and controlled transport of goods.

Types of Conveyor Chains

Conveyor chains are essential components in material handling systems, designed to facilitate the efficient transport of goods across various industrial and agricultural applications. They vary in design to accommodate specific operational requirements, such as load capacity, environmental conditions, and movement patterns. Below, several common types are outlined, each accompanied by illustrative images to demonstrate their structure and usage.

Overhead Conveyor Chains

Overhead conveyor chains suspend chains from ceiling-mounted tracks to transport items vertically or horizontally, frequently used in automotive and garment industries for space-efficient assembly and storage. This configuration optimizes floor space and allows for automated routing in complex factory layouts.

Slat Conveyor Chains

Slat conveyor chains consist of flat slats attached to chains, forming a continuous platform for transporting irregularly shaped or heavy objects in bottling and packaging lines. This type offers stability and easy cleaning, supporting high-speed operations in food processing and manufacturing facilities.

Roller Conveyor Chains

Roller conveyor chains utilize chains with integrated rollers to support and move loads smoothly along a track, commonly employed in assembly lines and warehouses for handling pallets or heavy items. This design reduces friction and enhances energy efficiency, making it suitable for continuous operations in manufacturing environments.

Pintle Conveyor Chains

Pintle conveyor chains employ open-barrel links secured by pins, providing high strength for applications such as manure spreaders and waste management in agriculture. Their robust construction resists corrosion and accommodates attachments for versatile material conveyance.