Descripción

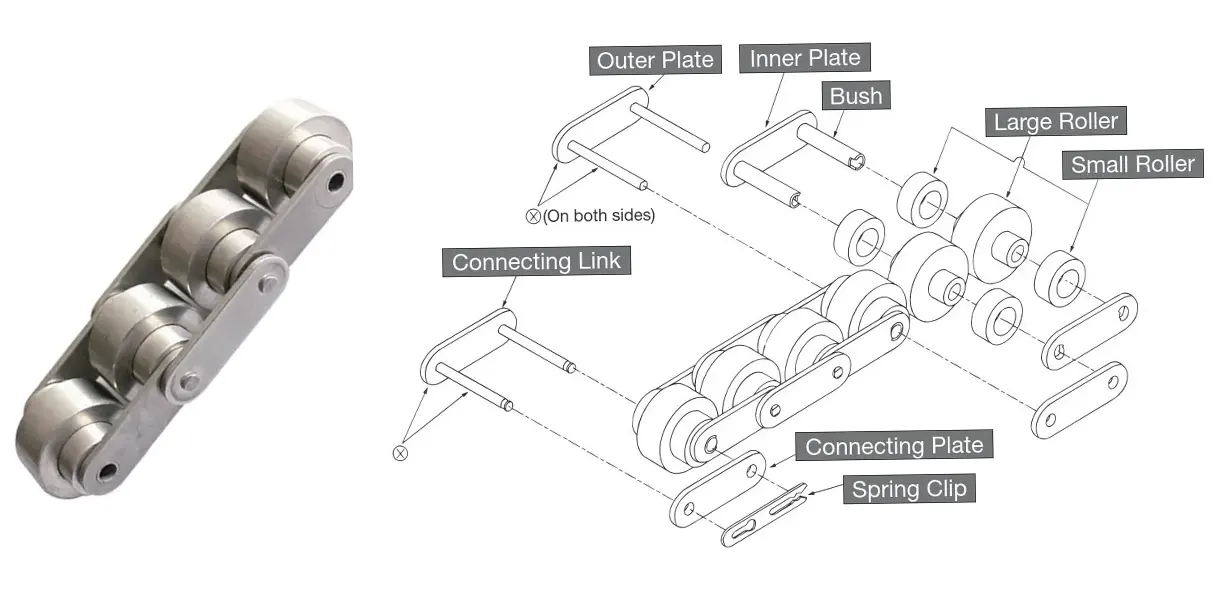

The Double Plus Chain 08BS-27-S16-00 stands as a premium replacement for BOSCH components, engineered specifically for integration within conveyor chain frameworks that demand exceptional performance. Constructed with high-grade materials such as 40Mn plates and 20CrMnMo pins, this chain exhibits outstanding wear resistance and fatigue endurance, facilitated by precise heat treatment processes achieving hardness levels from 43~50HRC for plates to over 79HRA for large rollers.

It excels in chain conveyor operations, offering low noise and broad temperature tolerance for applications in material handling, packaging, and food processing. Whether deployed in drag chain conveyor systems for bulk transport or overhead chain conveyor configurations for elevated routing, its double-plate structure ensures enhanced load capacity and smooth accumulation functions. For environments requiring flexibility, such as plastic chain conveyor variants, this product provides reliable power transmission with minimal lubrication needs, ultimately reducing operational costs and extending equipment lifespan in industrial settings.

Especificaciones técnicas

To facilitate informed decision-making, the following technical specifications detail the material composition, case depth, and heat treatment hardness for key components of the Double Plus Chain 08BS-27-S16-00. These parameters ensure compliance with industry standards and optimal performance in conveyor chain applications, allowing users to evaluate compatibility with specific operational requirements.

| Part name | Material | Case depth | Heat treatment hardness |

|---|---|---|---|

| Lámina | 40 millones | – | 43~50HRC |

| Alfiler | 20CrMnMo | 0.2~0.35 | 79~83HRA |

| Bush | 20Mn | 0.1~0.22 | 74~80HRA |

| Roller(S) | 20 | 0.25~0.35 | 76~80HRA |

| Roller(L) | 20 | 0.2~0.3 | >79HRA |

Model Selection Guide: When selecting from the Double Plus Chain series, consider the 08BS-27-S16-00 model for medium-load applications, such as standard material handling in packaging or assembly lines, where tensile strength up to 19.8 kN and moderate speeds are sufficient. For higher-load scenarios, such as heavy-duty drag chain conveyors in industrial bulk transport, opt for variants with reinforced plates or larger pitch sizes to accommodate loads exceeding 20 kN and enhanced fatigue resistance. In lighter-duty environments, like plastic chain conveyor systems for food processing, models with corrosion-resistant coatings are recommended to maintain hygiene and operational efficiency under variable temperatures.

Key Features and Benefits of Double Plus Chain 08BS-27-S16-00

Enhanced Durability: The double-plate construction, utilizing 40Mn material with 43-50HRC hardness, delivers exceptional resistance to wear and abrasion in high-stress conveyor chain environments. This design principle enhances breaking strength by distributing loads evenly across dual plates, making it ideal for prolonged exposure to abrasive materials or heavy-duty cycles, thereby extending operational lifespan and reducing replacement frequency.

Optimal Performance: With low noise levels achieved through precision-ground rollers and bushes (hardened to 74-80HRA), this chain ensures smooth, vibration-free operation in roller chain conveyor systems under continuous high loads. Its fatigue resistance stems from advanced heat treatment processes that optimize material microstructure, allowing reliable torque transmission and minimal energy loss in demanding industrial applications.

Versatile Compatibility: Serves as a direct BOSCH replacement, adaptable to various setups, including overhead chain conveyor for space-efficient designs.

Maintenance Efficiency: Wide operating temperature range and minimal lubrication requirements reduce upkeep, ideal for drag chain conveyor applications.

Precision Assembly: Fully automated production guarantees consistent quality, supporting integration in plastic chain conveyor lines for lighter industrial tasks.

Applications of Double Plus Chain in Conveyor Chain Systems

This Double Plus Chain is optimized for conveyor chain-driven systems in industries requiring robust material handling, such as elevators, printing presses, and textile machinery. It performs effectively in chain conveyor scenarios for power transmission, as well as specialized uses like drag chain conveyor for heavy-duty bulk movement or overhead chain conveyor for suspended operations, delivering consistent efficiency across diverse operational demands.

The chain’s accumulation mechanism, enabled by its dual-roller design, facilitates controlled buffering of items during transport, enhancing workflow in automated assembly lines. Additionally, its corrosion-resistant properties support reliable use in food processing environments, where hygiene and minimal downtime are critical, outperforming standard chains by maintaining alignment and reducing slippage under variable speeds.

Conveyor Chain Sprockets for Double Plus Conveyor Chains

Las ruedas dentadas de la cadena transportadora desempeñan un papel fundamental en el funcionamiento de los sistemas de transporte, ya que engranan directamente con la cadena para facilitar un movimiento suave y controlado. En concreto, los dientes de las ruedas dentadas se entrelazan con los eslabones de la cadena. cadena transportadoraLa transmisión de la fuerza rotacional desde un motor o mecanismo de transmisión impulsa la cadena hacia adelante. Esta combinación garantiza una alineación precisa, una regulación de velocidad adecuada y una distribución óptima de la carga. Factores clave como el número de dientes del piñón, el diámetro primitivo y la tensión de la cadena influyen en el rendimiento general del sistema; por ejemplo, un mayor número de dientes favorece un funcionamiento más suave y reduce el desgaste en aplicaciones de alta exigencia. La correcta selección y el mantenimiento de esta combinación minimizan la fricción, evitan el deslizamiento y mejoran la durabilidad, lo que la convierte en un elemento indispensable para las industrias que requieren un transporte fiable de materiales a granel.

Ofrecemos una gama completa de ruedas dentadas para transportadores diseñadas para complementar diversas cadenas transportadoras, garantizando una compatibilidad perfecta y una eficiencia óptima. Disponemos de opciones en diferentes materiales, tamaños y configuraciones para satisfacer necesidades operativas específicas. Para obtener más información o recomendaciones personalizadas, por favor Contacta con nuestro equipo para analizar sus necesidades.

¿Por qué elegirnos?

Como fabricante líder de componentes de transmisión, Ever-power se distingue por su ingeniería de precisión, precios competitivos y un servicio al cliente excepcional. Nuestra clientela global destaca la durabilidad e integración de nuestras cadenas, lo que fomenta relaciones a largo plazo en los sectores agrícola e industrial. A continuación, presentamos tres razones de peso para asociarse con nosotros y lograr una eficiencia y confiabilidad óptimas.

Excelencia del producto:

Nuestros productos se fabrican con materiales de alta calidad, como aceros de aleación de primera calidad, combinados con técnicas de producción avanzadas, incluyendo forja de precisión y líneas de ensamblaje automatizadas. Se someten a pruebas rigurosas para superar los estándares ASME/ANSI, lo que se traduce en una menor elongación y una mayor resistencia a la fatiga. Esto garantiza un tiempo de inactividad mínimo en aplicaciones críticas, con opciones personalizables disponibles para ofrecer soluciones versátiles y de alto rendimiento adaptadas a necesidades específicas.

Precios competitivos:

Ever-power mantiene precios competitivos gracias a procesos de fabricación eficientes y un abastecimiento estratégico, maximizando el retorno de la inversión sin sacrificar la calidad. Mantenemos altos niveles de inventario para garantizar una rápida tramitación de pedidos y plazos de entrega cortos, logrando entregas en tan solo 2 a 4 semanas para artículos estándar. Las empresas se benefician de menores gastos a largo plazo debido a la reducción de reemplazos, lo que permite un crecimiento escalable en mercados competitivos.

Servicio excepcional:

Ofrecemos un soporte integral que va más allá de la venta, incluyendo consultas personalizadas, asesoramiento sobre mantenimiento y una garantía de calidad estándar de un año en todos los productos, respaldada por estrictas medidas de control de calidad como la certificación de materiales y las inspecciones por lotes. Nuestro equipo ofrece prototipado rápido, visitas a la fábrica previa solicitud y resolución proactiva de problemas para optimizar el éxito operativo, lo que nos posiciona como un socio confiable y colaborativo.

Preguntas frecuentes (FAQ)

What advantages does this chain offer in conveyor chain systems?

It provides high strength and low noise, making it a dependable choice for extended use in industrial conveyor setups.

Is it compatible as a BOSCH replacement?

Yes, designed precisely to match BOSCH specifications, ensuring seamless integration without modifications.

How does it handle roller chain conveyor demands?

With its heat-treated components, it supports high-speed and high-load operations effectively.

Can it be used in overhead chain conveyor installations?

Absolutely, its durable design accommodates elevated and space-constrained environments.

What makes it suitable for drag chain conveyor applications?

The double-plate structure enhances load-bearing capacity for bulk material transport.

Is it adaptable to plastic chain conveyor variants?

Yes, offering flexibility and corrosion resistance for lighter-duty conveyor needs.

What maintenance practices are recommended for the Double Plus Chain?

Regular inspection for wear on pins and rollers is advised, along with periodic lubrication using compatible oils to maintain optimal performance. Clean the chain periodically to remove debris, and monitor alignment to prevent uneven stress, ensuring an extended service life in conveyor chain systems.

Does this chain support customization options?

Yes, we offer customization for length, material variations, and attachment configurations to meet specific operational requirements, provided details are discussed during the ordering process for precise adaptation to unique conveyor chain applications.

How is the quality of this chain assured?

Quality is ensured through rigorous manufacturing standards, including automated assembly, heat treatment verification, and tensile strength testing exceeding 18.0 kN. All components undergo material certification and batch inspections to comply with industry benchmarks for reliability and durability.

What should be done if the chain exhibits signs of fatigue or wear?

Immediately cease operation and inspect for damaged links or elongation beyond 3% of the original pitch. Replace affected sections promptly, and consult our technical support for root cause analysis to prevent recurrence in high-load conveyor chain environments.

Opiniones de clientes

The following comments are summarized from real customer feedback across different countries and industries; some details are abbreviated for privacy.

⭐⭐⭐⭐⭐ A****r, Maintenance Lead at PackPro Systems, USA

We’ve been using the 08BS-27-S16-00 chain on our high-speed packaging line since early 2023, and it has significantly reduced chain elongation issues under constant operation. The support team was quick to clarify compatibility specs during our initial query.

⭐⭐⭐⭐⭐ M****k, Operations Specialist at LogiFlow GmbH, Germany

This replacement chain integrated well into our conveyor setup for automotive parts handling, showing good resistance to abrasion after six months of use. Delivery arrived on time, though the packaging could be more compact to reduce waste.

⭐⭐⭐⭐⭐ E****n, Technician at MechDrive Ltd., UK

Installed the Double Plus chain in our warehouse sorting system in 2024; it handles variable loads smoothly without frequent adjustments. Customer service provided detailed installation tips, which helped avoid minor alignment errors.

⭐⭐⭐⭐ S****h, Supply Manager at IndusTech Solutions, India

The chain’s tensile strength has held up in our humid manufacturing environment since mid-2023, minimizing downtime on assembly lines. Logistics were efficient across borders, but we’d suggest including multilingual instructions for broader accessibility.

⭐⭐⭐⭐⭐ J****e, Engineer at TransEquip Corp., Canada

Using this chain on overhead conveyors for material transport since 2022, it offers reliable performance with low noise levels. The product arrived securely packaged, and the team’s response to our follow-up questions was professional and timely.

⭐⭐⭐⭐ L****o, Quality Inspector at FlowMech Italy, Italy

It performs adequately in our food processing line, with better wear resistance than previous models after a year of operation. While the quality is solid, a slight delay in shipping was resolved promptly by support.

⭐⭐⭐⭐⭐ K****i, Facility Coordinator at AsiaLift Industries, Japan

The 08BS-27-S16-00 has improved efficiency in our robotic assembly setup, reducing maintenance intervals. Expert guidance from the service team ensured seamless integration with our Bosch-compatible systems.

⭐⭐⭐⭐⭐ T****m, Procurement Analyst at ElevaTech Australia, Australia

This chain has been reliable for heavy-duty applications in mining equipment handling, though we noted minor initial lubrication needs. Overall, prompt delivery and robust construction make it a worthwhile replacement.