Description

Our conveyor chains with plastic rollers are engineered for efficiency and reliability in various industrial applications. Featuring lightweight plastic rollers that minimize noise and wear, these chains ensure seamless material transport while enhancing system longevity. Available in standard sizes such as 40-P, 50-P, 60-P, 80-P, and A2050-P, they are particularly suited for environments requiring low-maintenance solutions, such as automated conveyor systems where precision and durability are paramount.

Product Specifications

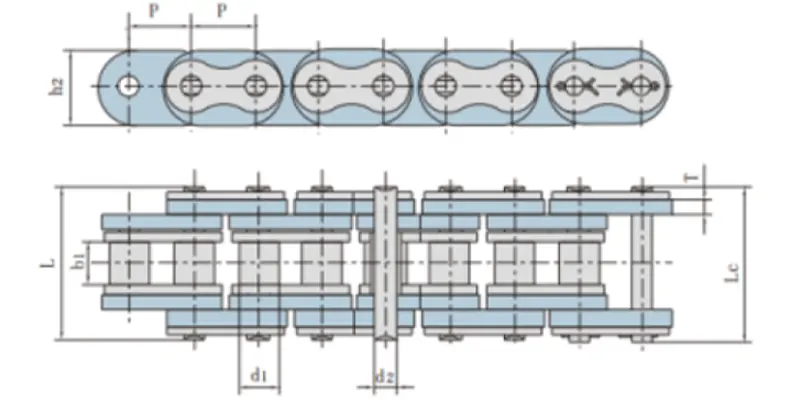

The following table details the essential dimensions and mechanical properties of our conveyor chains with plastic rollers, facilitating accurate engineering assessments and system integration. Use these parameters to verify compatibility with sprockets, loads, and operational speeds in your conveyor setup.

| Chain No. | Pitch (P) mm | Roller Diameter (d1 max) mm | Inner Plate Width (b1 min) mm | Pin Diameter (d2 max) mm | Pin Length (L max) mm | Inner Plate Depth (Lc max) mm | Plate Height (h2 max) mm | Plate Thickness (T) mm | Ultimate Tensile Strength (Q min) kN/lbf | Average Tensile Strength (Q0) kN | Weight per Meter (q kg/m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-P | 12.70 | 7.95 | 7.85 | 3.96 | 16.6 | 17.8 | 12.00 | 1.50 | 14.10/3205 | 17.5 | 0.56 |

| 50-P | 15.87 | 10.16 | 9.40 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 22.20/5045 | 29.4 | 0.96 |

| 60-P | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18.00 | 2.42 | 31.80/7227 | 41.5 | 1.35 |

| 80-P | 25.40 | 15.88 | 15.75 | 7.92 | 32.7 | 35.0 | 24.00 | 3.25 | 56.70/12886 | 69.4 | 2.26 |

| A2050-P | 31.75 | 10.16 | 9.40 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 22.20/5045 | 28.1 | 0.61 |

Selection Guide: When selecting a conveyor chain with plastic rollers, consider load requirements and operational environments. The 40-P model suits light loads (up to 17.5 kN tensile strength) in clean, low-speed settings like small-scale packaging. For medium loads (up to 41.5 kN), opt for 50-P, 60-P, or A2050-P, ideal for moderate-duty applications in humid or corrosive environments such as food processing. The 80-P is recommended for heavy loads (up to 69.4 kN) in demanding industrial scenarios, ensuring robustness while maintaining low-friction performance.

Features and Advantages of Conveyor Chains with Plastic Rollers

These conveyor chains with plastic rollers incorporate advanced engineering to minimize operational friction, extend service life, and optimize performance in demanding material handling environments. They represent a reliable solution for modern conveyor systems, offering enhanced efficiency through reduced wear and energy consumption. The following subsections detail the primary features and advantages.

Structural Durability and Strength

Constructed with precision-engineered links, pins, and plates, these chains exhibit superior tensile strength, as evidenced by ultimate values ranging from 14.10 kN/lbf to 56.70 kN/lbf across models. This robust design ensures resistance to heavy loads and prolonged operational cycles, making them suitable for high-stress applications while maintaining structural integrity over time.

Maintenance Efficiency and Corrosion Resistance

The integration of plastic rollers significantly reduces the need for frequent lubrication and maintenance, as they inherently resist corrosion and environmental degradation. This feature is particularly advantageous in humid, chemical-exposed, or clean-room settings, where traditional metal components may fail prematurely, thereby lowering overall downtime and operational costs.

Operational Efficiency and Noise Reduction

Plastic rollers facilitate smoother engagement with sprockets, resulting in lower friction coefficients and quieter operation compared to all-metal alternatives. This leads to improved energy efficiency in conveyor systems and enhances workplace safety by minimizing noise pollution, which is essential in industries prioritizing ergonomic conditions.

Versatility and Customization Potential

These chains are adaptable to various conveyor chain types and configurations, supporting seamless integration into existing setups. Their lightweight construction, with weights as low as 0.56 kg/m, allows for easier installation and handling, while options for customization in length, attachments, or materials further tailor them to specific industrial requirements.

Working Principle

The operational mechanism of these conveyor chains with plastic rollers is based on a precise, load-bearing linkage system that ensures efficient power transmission and material conveyance. The plastic rollers interface directly with compatible sprockets, converting rotational motion from drive sources into linear movement along the conveyor path. Chain links, reinforced by high-strength pins and plates, maintain alignment and distribute loads evenly, preventing elongation or failure under stress.

To optimize performance, users should ensure proper sprocket alignment—typically within 0.5 degrees of parallelism—and maintain chain tension at 1-2% of the pitch length to avoid slack or excessive wear. Regular monitoring of roller wear indicators, such as surface deformation or increased noise, provides guidance for timely replacements, aligning with ISO standards for conveyor chain maintenance to maximize system reliability and minimize energy losses in material handling processes.

Applications of Conveyor Chains with Plastic Rollers

These chains are versatile components in industrial automation, offering reliable performance across diverse sectors where hygiene, efficiency, and durability are essential. Their design supports integration into both new and retrofitted systems, providing consistent operation under varying loads and speeds.

Food and beverage processing lines: where corrosion-resistant plastic rollers ensure compliance with sanitary standards and facilitate low-noise transport of perishable goods.

Packaging and assembly operations: benefiting from the chains’ compatibility with plastic chain conveyor setups to handle delicate items with minimal vibration and high precision.

Automated warehouses and logistics facilities: utilizing the chains’ ability to manage heavy-duty loads in complex conveyor systems for streamlined inventory movement and order fulfillment.

Pharmaceutical manufacturing environments: where low-maintenance features and clean operation prevent contamination and support continuous production cycles.

Electronics assembly lines: leveraging reduced friction to transport sensitive components without static buildup or damage, enhancing overall yield and efficiency.

Conveyor Chain Sprockets for Conveyor Chains

Conveyor chain sprockets play a critical role in the functionality of conveyor systems by engaging directly with the chain to facilitate smooth and controlled movement. Specifically, the sprockets’ teeth interlock with the links of the conveyor chain, transferring rotational force from a motor or drive mechanism to propel the chain forward. This pairing ensures precise alignment, speed regulation, and load distribution, with key factors such as the sprocket’s tooth count, pitch diameter, and chain tension influencing overall system performance—higher tooth counts, for instance, promote smoother operation and reduced wear in heavy-duty applications. Proper selection and maintenance of this combination minimize friction, prevent slippage, and enhance durability, making it indispensable for industries requiring reliable bulk material transport.

We offer a comprehensive range of conveyor sprockets designed to complement various conveyor chains, ensuring seamless compatibility and optimized efficiency. These include options in different materials, sizes, and configurations to suit specific operational needs. For further details or customized recommendations, please contact our team to discuss your requirements.

Why Choose Us

As a premier manufacturer of transmission components, Ever-power distinguishes itself through engineering precision, value-driven pricing, and client-centric support. Our global clientele highlights our chains’ durability and integration, fostering long-term partnerships in the agricultural and industrial sectors. Below are three compelling reasons to partner with us for optimal efficiency and reliability.

Product Excellence:

Our products are manufactured using high-quality materials such as premium alloy steels, combined with advanced production techniques including precision forging and automated assembly lines. They undergo rigorous testing to surpass ASME/ANSI standards, resulting in reduced elongation and enhanced fatigue life. This ensures minimal downtime in critical applications, with customizable options available to deliver versatile, high-performance solutions tailored to specific needs.

Competitive Pricing:

Ever-power maintains competitive rates through efficient manufacturing processes and strategic sourcing, maximizing return on investment without compromising quality. We keep substantial inventory levels to support quick order fulfillment and short lead times, often achieving delivery within 2-4 weeks for standard items. Businesses benefit from lower long-term expenses due to fewer replacements, enabling scalable growth in competitive markets.

Exceptional Service:

We provide comprehensive support beyond sales, including tailored consultations, maintenance guidance, and a standard one-year quality warranty on all products, backed by strict quality control measures such as material certification and batch inspections. Our team offers rapid prototyping, factory tours upon request, and proactive issue resolution to enhance operational success, positioning us as a reliable, collaborative partner.

Frequently Asked Questions (FAQ)

Q: What are the main advantages of plastic conveyor chain over traditional metal ones?

A: Plastic conveyor chains offer reduced weight, corrosion resistance, and quieter operation, making them ideal for sensitive environments like food processing.

Q: How do conveyor chain rollers contribute to system efficiency?

A: Conveyor chain rollers, especially plastic variants, decrease friction and wear, leading to lower energy consumption and longer service intervals in chain conveyors.

Q: Can these chains be customized for specific conveyor chain parts requirements?

A: Yes, we offer customization options for conveyor chain parts, including adjustments to pitch and roller materials to fit unique application needs.

Q: Are these suitable for high-load chain conveyor applications?

A: Absolutely, with tensile strengths up to 69.4 kN, they handle demanding loads in various chain conveyor scenarios.

Q: How should I maintain conveyor chains with plastic rollers to ensure longevity?

A: Perform regular visual inspections for signs of wear on rollers and links, clean with non-abrasive solutions to remove debris, and monitor tension levels to prevent elongation; minimal lubrication is needed due to the self-lubricating properties of plastic components.

Q: What quality assurance measures are in place for these conveyor chains?

A: Our chains undergo rigorous testing in accordance with ISO standards, including tensile strength verification and material composition analysis, to guarantee consistent performance and compliance with industry benchmarks for durability and reliability.

Q: What is the expected lifespan of these conveyor chains in typical applications?

A: Under standard conditions with proper maintenance, these chains can achieve 5-10 years of service life, depending on load factors and environmental exposure, supported by their high tensile strengths and corrosion-resistant design.

Customer Reviews

⭐⭐⭐⭐⭐ J****n, Operations Manager at FunWorld Attractions, Canada

The conveyor chain has proven exceptionally durable in our high-traffic ride systems, with the plastic rollers reducing noise and maintenance needs significantly since installation last spring.

⭐⭐⭐⭐⭐ E****a, Technical Engineer at Adventure Park Solutions, Germany

Excellent packaging ensured the chains arrived undamaged, and the smooth operation of the 60-P variant has enhanced our conveyor efficiency without any issues over the past six months.

⭐⭐⭐⭐ R****t, Procurement Specialist at ThrillRide Enterprises, Australia

While the delivery was slightly delayed due to customs, the quality of these chains with plastic rollers exceeded expectations, providing reliable performance in our demanding environment.

⭐⭐⭐⭐⭐ S****h, Maintenance Lead at EcoFun Parks Ltd., UK

The chains integrated seamlessly into our existing setup since 2023, and the customer support team’s detailed installation advice made the process effortless and timely.

⭐⭐⭐⭐⭐ L****o, Supply Chain Coordinator at Vista Amusements, Italy

Fast logistics and secure packaging protected the chains during transit, allowing us to resume operations quickly with improved load handling.

⭐⭐⭐⭐ K****m, Facility Supervisor at DreamLand Resorts, South Korea

These chains have held up well under continuous use, though I appreciated the prompt response from service when clarifying compatibility for the 80-P model.

⭐⭐⭐⭐⭐ T****r, Engineering Director at Peak Entertainment Group, USA

Since switching to the 60-P rollers two years ago, we’ve seen a marked reduction in wear, complemented by the manufacturer’s responsive technical support.

⭐⭐⭐⭐⭐ P****a, Quality Assurance Officer at Horizon Parks Inc., Spain

The robust design of these conveyor chains ensures consistent performance, and the overall experience from order placement to delivery was professional and efficient.