Description

Our 667H-00 Steel Pintle Chain serves as a robust conveyor chain designed specifically for manure spreaders, ensuring efficient material handling in agricultural operations. Constructed from premium materials including 40Mn for chain links and 40Cr for pins, this chain conveyor delivers superior tensile strength and corrosion resistance, making it suitable for heavy-duty applications. With components like connecting pins and cotter pins optimized for easy assembly and maintenance, it minimizes downtime and enhances productivity on farms.

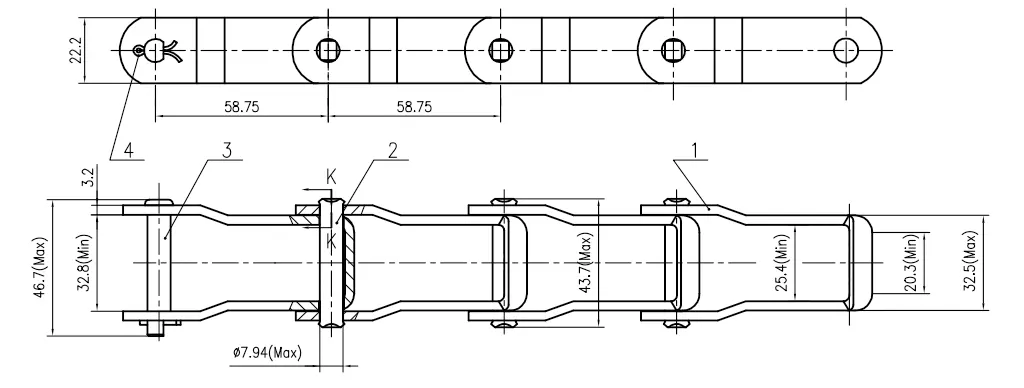

Specifications of 667H-00 Steel Pintle Chain

To facilitate informed decision-making, the following table outlines the key specifications for the 667H-00 Steel Pintle Chain, including part numbers, materials, and weights. This detailed breakdown ensures transparency regarding component quality and compatibility, allowing for precise integration into manure spreader systems or similar conveyor applications.

| No. | Part Number | Part Name | Material | Weight (g) |

|---|---|---|---|---|

| 1 | 667H-00-01 | Chain Links | 40Mn | 92.9 |

| 2 | 667H-00-02 | Pins | 40Cr | 16.9 |

| 3 | 667H-00-07 | Connecting Pins | 40Cr | 17.37 |

| 4 | GB/T 912.5X16 | Cotter Pins | – | – |

| 5 | 667H-00-01 | Chain Links | 40Mn | 92.9 |

| 6 | 667H-00-02 | Pins | 20CrMnMo | 16.9 |

| 7 | 667H-00-07 | Connecting Pins | 20CrMnMo | 17.9 |

| 8 | GB/T 912.5X16 | Cotter Pins | – | – |

Note:*For custom requirements or further technical details, we recommend consulting with our engineering team to optimize performance in your specific setup.

Key Features and Benefits of Our Conveyor Chain

By incorporating advanced materials and precise manufacturing techniques, this conveyor chain minimizes operational disruptions while maximizing efficiency and cost-effectiveness. Below, we outline the primary attributes that distinguish this product, ensuring it meets the rigorous needs of professionals in material handling.

High-Strength Construction: Utilizes 40Mn and 40Cr/20CrMnMo alloys for enhanced durability, reducing wear in drag chain conveyor setups. This composition provides superior resistance to tensile forces and fatigue, allowing the chain to endure prolonged exposure to heavy loads and abrasive materials without deformation or failure.

Precision Engineering: Components like pins and links ensure smooth integration into roller chain conveyor applications, supporting consistent performance. The exact tolerances in machining facilitate seamless articulation, which reduces friction and energy consumption, thereby optimizing the overall efficiency of the conveyor system.

Versatile Applications: Perfect for manure spreaders and similar overhead chain conveyor environments, with easy maintenance to extend service life. Its adaptable design accommodates various configurations, from ground-based agricultural machinery to elevated industrial systems, enabling reliable operation across diverse scenarios while simplifying routine upkeep through accessible disassembly features.

Quality Assurance: Each part undergoes rigorous testing to meet industry standards, offering value through reduced replacement frequency. Comprehensive quality control protocols, including stress testing and material verification, guarantee compliance with international specifications, resulting in a product that not only performs reliably but also contributes to long-term economic benefits by lowering maintenance expenditures.

In summary, these features collectively position the 667H-00 Steel Pintle Chain as a reliable solution within chain conveyor systems, fostering enhanced productivity and operational resilience for users in agriculture and beyond.

Application and Usage Scenarios for Conveyor Chain

The conveyor chain is engineered for robust performance in agricultural environments, where reliable material handling is essential for operational efficiency. Its design excels in applications involving bulk material transport, particularly in settings that demand high tensile strength and resistance to wear from abrasive substances. Below, we explore key scenarios, with a primary focus on its integration in manure spreaders, supplemented by broader agricultural uses to illustrate its versatility.

Primary Use in Manure Spreaders

In manure spreaders, this conveyor chain plays a pivotal role in facilitating even distribution of organic materials across fields, thereby enhancing soil fertility and structure. It drives the apron floor system—a conveyor mechanism that steadily pulls manure toward the discharge beaters or slingers for uniform spreading. This process is crucial for large-scale farming operations, as it minimizes clumping and ensures consistent nutrient application, reducing waste and optimizing crop yields. Farmers benefit from its ability to handle viscous, semi-solid loads under varying terrain conditions, such as uneven fields or wet soil, without compromising speed or reliability. For instance, in truck-mounted or tractor-pulled spreaders, the chain’s precise links and pins maintain tension, preventing slippage and enabling continuous operation during extended field sessions.

Additional Agricultural Applications

Beyond manure spreaders, the chain supports a range of farming tasks that require durable conveyance solutions:

Fertilizer and Salt-Sand Spreaders: It efficiently transports granular materials like fertilizers or de-icing salts, ensuring controlled release to promote even coverage and prevent over-application in crop rows or roadways.

Hay Hauling and Elevator Systems: The chain aids in elevating and moving bales or loose hay, streamlining storage and feeding processes in barns or silos with minimal downtime.

Bunk Feeders and Feeding Machines: In livestock operations, they convey feed mixtures to troughs, supporting automated distribution that reduces labor and maintains hygiene standards.

General Mechanized Farming Equipment: For broader landscape management, it integrates into seed spreaders or composting machinery, handling bulk organics to improve soil health across expansive acres.

Conveyor Chain Sprockets for 667H-00 Steel Pintle Chains

Conveyor chain sprockets play a critical role in the functionality of conveyor systems by engaging directly with the chain to facilitate smooth and controlled movement. Specifically, the sprockets’ teeth interlock with the links of the conveyor chain, transferring rotational force from a motor or drive mechanism to propel the chain forward. This pairing ensures precise alignment, speed regulation, and load distribution, with key factors such as the sprocket’s tooth count, pitch diameter, and chain tension influencing overall system performance—higher tooth counts, for instance, promote smoother operation and reduced wear in heavy-duty applications. Proper selection and maintenance of this combination minimize friction, prevent slippage, and enhance durability, making it indispensable for industries requiring reliable bulk material transport.

We offer a comprehensive range of conveyor sprockets designed to complement various conveyor chains, ensuring seamless compatibility and optimized efficiency. These include options in different materials, sizes, and configurations to suit specific operational needs. For further details or customized recommendations, please contact our team to discuss your requirements.

Installation and Maintenance Considerations

To maximize performance in these scenarios, proper installation involves aligning the chain with compatible sprockets and adjusting tension using standard devices to avoid elongation. In manure spreaders, secure the pintle hooks firmly to the apron slats for seamless movement.

Maintenance is straightforward: conduct regular inspections for signs of corrosion or pin wear, especially after exposure to moist manure, and apply suitable lubricants to extend service life. This proactive approach not only sustains efficiency but also aligns with sustainable farming practices by reducing equipment replacements.

Why Choose Us

As a premier manufacturer of transmission components, Ever-power distinguishes itself through engineering precision, value-driven pricing, and client-centric support. Our global clientele highlights our chains’ durability and integration, fostering long-term partnerships in the agricultural and industrial sectors. Below are three compelling reasons to partner with us for optimal efficiency and reliability.

Product Excellence:

Building on U.S. Tsubaki’s innovation and Renold’s designs, our products undergo rigorous testing to surpass ASME/ANSI standards, yielding reduced elongation and enhanced fatigue life. Clients praise this for minimizing downtime in critical applications, with customizable options ensuring versatile, high-performance solutions.

Competitive Pricing:

Ever-power offers elite pintle chains at competitive rates, maximizing return on investment without quality compromises. Echoing Diamond Chain’s affordability strategy, we use streamlined manufacturing and direct procurement to provide cost-effective options that lower long-term expenses. Businesses report substantial savings through fewer replacements, supporting scalable growth in a competitive market.

Exceptional Service:

We extend support beyond sales, with a team offering tailored guidance from consultations to maintenance advice. Inspired by client focus and dependability, we provide factory tours, rapid prototyping, and proactive problem resolution. Testimonials affirm our role in enhancing operational success, making us a reliable, collaborative partner.

Frequently Asked Questions (FAQ)

Q: What materials are used in the 667H-00 Steel Pintle Chain?

A: The chain features 40Mn for links and 40Cr or 20CrMnMo for pins, providing excellent strength for demanding conveyor chain types.

Q: How does this chain perform in drag chain conveyors?

A: It offers superior resistance to abrasion and fatigue, ensuring reliable operation in drag chain conveyor systems for manure handling.

Q: Is this suitable for roller chain conveyor setups?

A: Yes, its precise components make it compatible with roller chain conveyor designs, enhancing efficiency in agricultural applications.

Q: Can it be used in overhead chain conveyors?

A: While primarily for ground-level spreaders, its durable build supports adaptations in overhead chain conveyor configurations with proper engineering.

Q: What maintenance is required for chain conveyors using this product?

A: Regular inspection of pins and links, along with lubrication, prevents wear in chain conveyors, prolonging operational life.

Q: Do you offer customization options for the chain?

A: Yes, we provide customization services, including modifications to length, material variants, or specific attachments, to meet unique operational requirements in conveyor systems.

Q: How is the quality of this conveyor chain assured?

A: Quality is ensured through rigorous material testing, precision manufacturing processes, and compliance with international standards such as ISO certifications, guaranteeing consistent performance and reliability.

Q: What is the warranty period for this product?

A: This conveyor chain comes with a standard one-year warranty against manufacturing defects, with extended options available upon request to support long-term usage in demanding environments.

Q: How can I obtain a quote or place an order?

A: Contact our sales team via the RFQ form on our website or email for a personalized quote; orders can be processed efficiently with details on quantity, specifications, and delivery timelines.

Customer Reviews

⭐⭐⭐⭐⭐ J****n, Farm Equipment Manager at AgriTech Farms Ltd., Canada

The steel pintle chain demonstrates exceptional durability in demanding agricultural environments, with minimal stretching even after extended use. The packaging was secure, preventing any damage during transit.

⭐⭐⭐⭐ T****s, Operations Lead at Rural Machinery Co., USA

While installation was straightforward, the chain’s resistance to corrosion has proven invaluable for our manure spreader operations. Delivery arrived ahead of schedule, which was a pleasant surprise.

⭐⭐⭐⭐⭐ A****r, Maintenance Engineer at Harvest Pro Inc., Australia

This conveyor chain offers reliable performance under heavy loads, with smooth links that reduce operational friction. Customer support was responsive and knowledgeable, assisting with compatibility questions efficiently.

⭐⭐⭐⭐ L****e, Supervisor at GreenField Agri Services, UK

The product’s sturdy build handles abrasive materials well, though we noted a slight initial adjustment period. Logistics were handled professionally, ensuring timely arrival without issues.

⭐⭐⭐⭐⭐ R****t, Equipment Specialist at FarmLink Enterprises, USA

Impressive tensile strength and wear resistance make this chain ideal for intensive use in spreaders. The team provided detailed product specs promptly, enhancing our purchasing confidence.

⭐⭐⭐⭐⭐ S****a, Technical Coordinator at EcoFarm Solutions, New Zealand

Packaging was robust and eco-friendly, protecting the chain during international shipping. Its precision engineering ensures consistent maneuverability, exceeding our expectations for quality.

⭐⭐⭐⭐ M****k, Operations Manager at Valley Agri Tech, USA

The chain integrates seamlessly with our equipment, offering longevity against daily wear. Service attitude from the sales team was exemplary, with quick follow-ups on our order status.

⭐⭐⭐⭐⭐ K****y, Maintenance Director at Prairie Equipment Group, Canada

Superior material quality resists fatigue in harsh conditions, promoting efficient operations. Combined with efficient logistics and attentive customer service, this has been a worthwhile investment.